Machining in Vietnam

High-precision CNC manufacturing, engineering expertise, and export-ready production for global industries.

About Us

Why Choose VNM

Vietnam Machining (VNM) delivers precision machining supported by experienced engineers, modern CNC equipment, and a nationwide supplier network. We provide tight-tolerance components, consistent production quality, and cost-efficient manufacturing that meets the expectations of U.S. and EU buyers. With strong technical capability, transparent workflows, and reliable export performance, VNM is a trusted partner for industrial-grade CNC machining in Vietnam.

Engineering-Led Precision

Our machining workflows are guided by experienced engineers who ensure proper DFM, stable tolerances, and optimized toolpaths for complex industrial components.

Export-Ready Manufacturing Network

VNM partners with certified CNC factories across Vietnam, providing capacity, scalability, and consistent quality for U.S. and EU production requirements.

Competitive, Reliable Production

We combine cost-efficient machining with strict QC standards, delivering high-value components with predictable lead times and dependable repeatability.

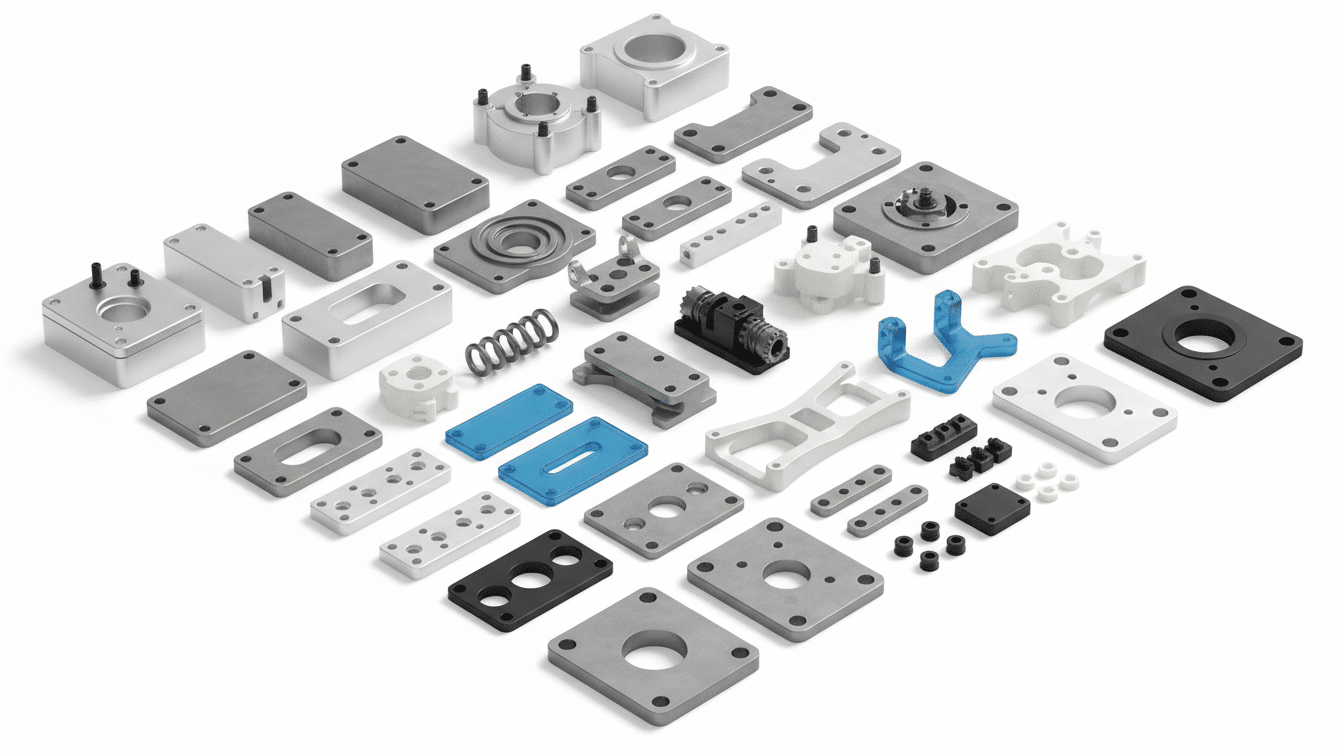

Our Capabilities

Machining Capabilities

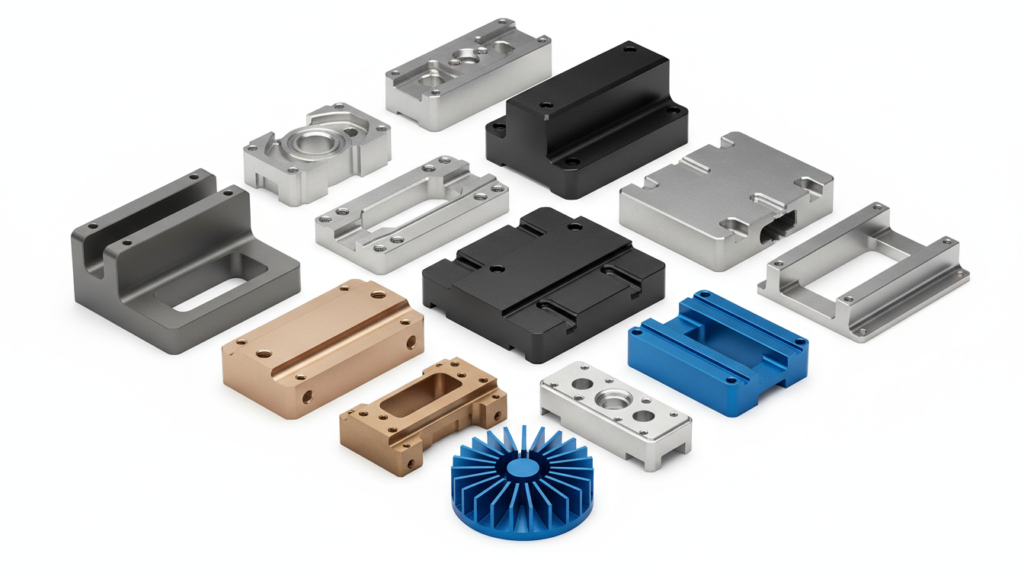

CNC Milling

Best for: Complex geometries, multi-surface parts, structural assemblies.

Description: High-precision 3-axis, 4-axis, and 5-axis milling for aluminum, steel, copper, brass, and engineering plastics. Ideal for components requiring accurate profiles and tight dimensional control.

Applications: Housings, brackets, enclosures, plates, covers, precision frames.

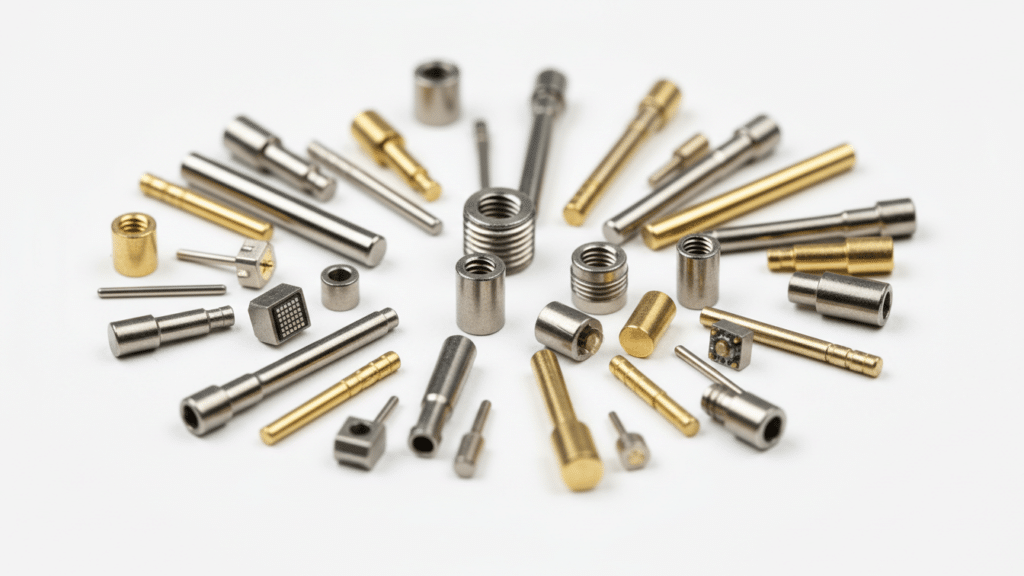

CNC Turning

Best for: Rotational components with uniform geometry.

Description: High-speed turning and turn-mill processes for shafts, bushings, connectors, and threaded parts. Offers stable repeatability for both small and large diameters.

Applications: Shafts, pins, spacers, fasteners, flanges, couplings.

Swiss Machining

Best for: Small, intricate, high-volume parts requiring extreme accuracy.

Description: Swiss turning provides exceptional precision for micro-diameter components with tight tolerances and consistent repeatability at scale.

Applications: Electronic pins, micro-shafts, sensor parts, medical fittings, automation components.

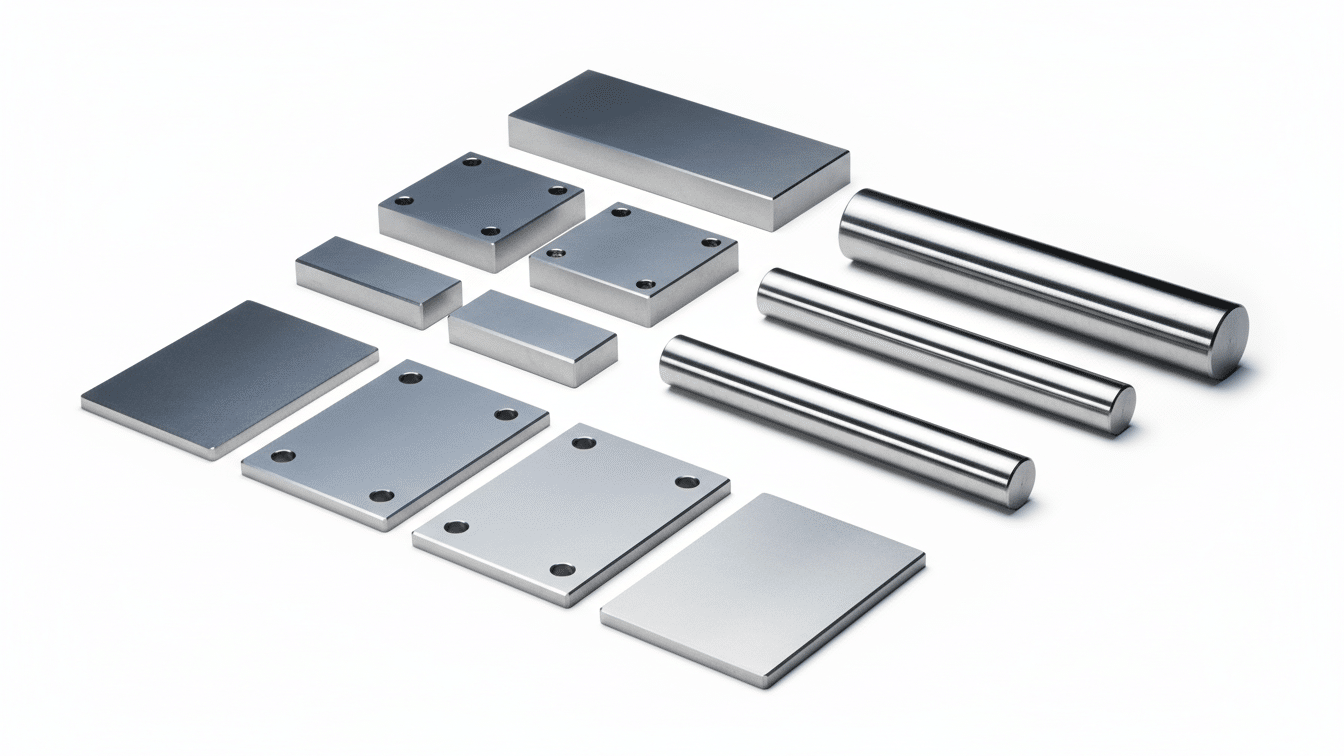

Grinding (Surface, OD/ID)

Best for: Fine surface finishes and high-accuracy flatness or roundness.

Description: Precision grinding processes to refine surface quality, achieve tight tolerances, and stabilize geometries after machining.

Applications: Wear plates, precision rods, hardened steel parts, sealing surfaces.

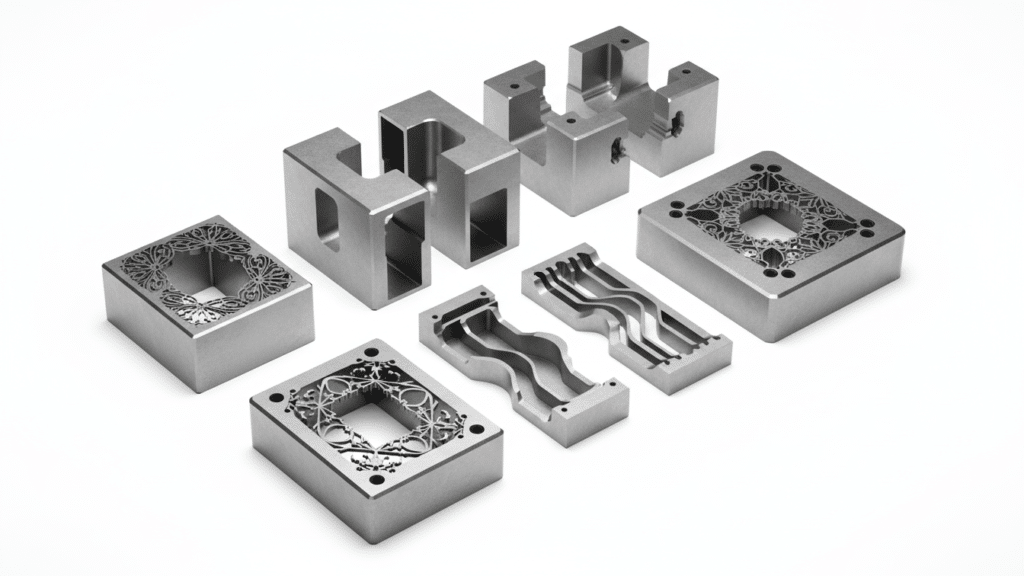

EDM & Wire Cutting

Best for: Intricate shapes, hardened materials, and internal corners.

Description: Electrical discharge machining enables precise cutting of complex profiles and geometries not achievable with standard tooling.

Applications: Tooling components, molds, dies, sharp corner profiles, internal cavities.

Prototyping & Low-Volume Machining

Best for: R&D, design validation, and small-batch manufacturing.

Description: Rapid CNC machining with quick lead times, dimensional reporting, and material flexibility for fast iteration cycles.

Applications: Prototype housings, test components, functional samples, pilot-run parts.

Our Capabilities

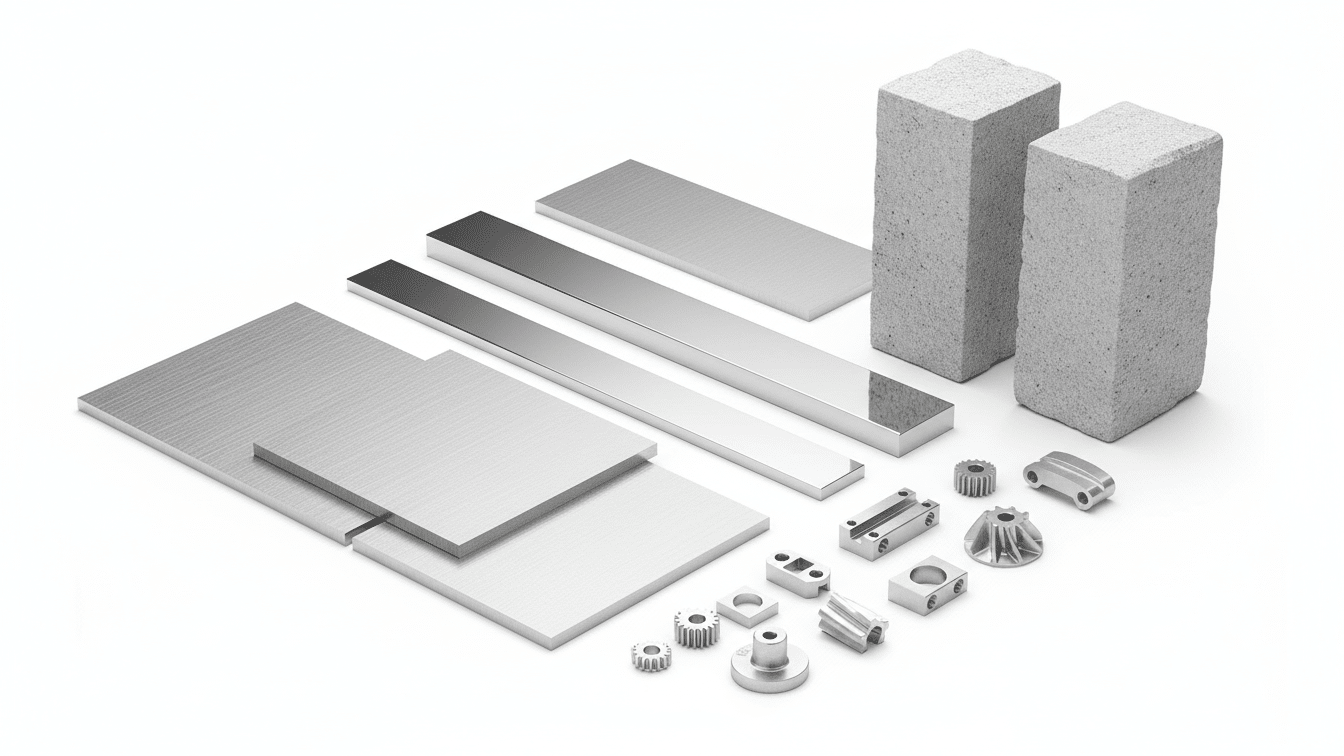

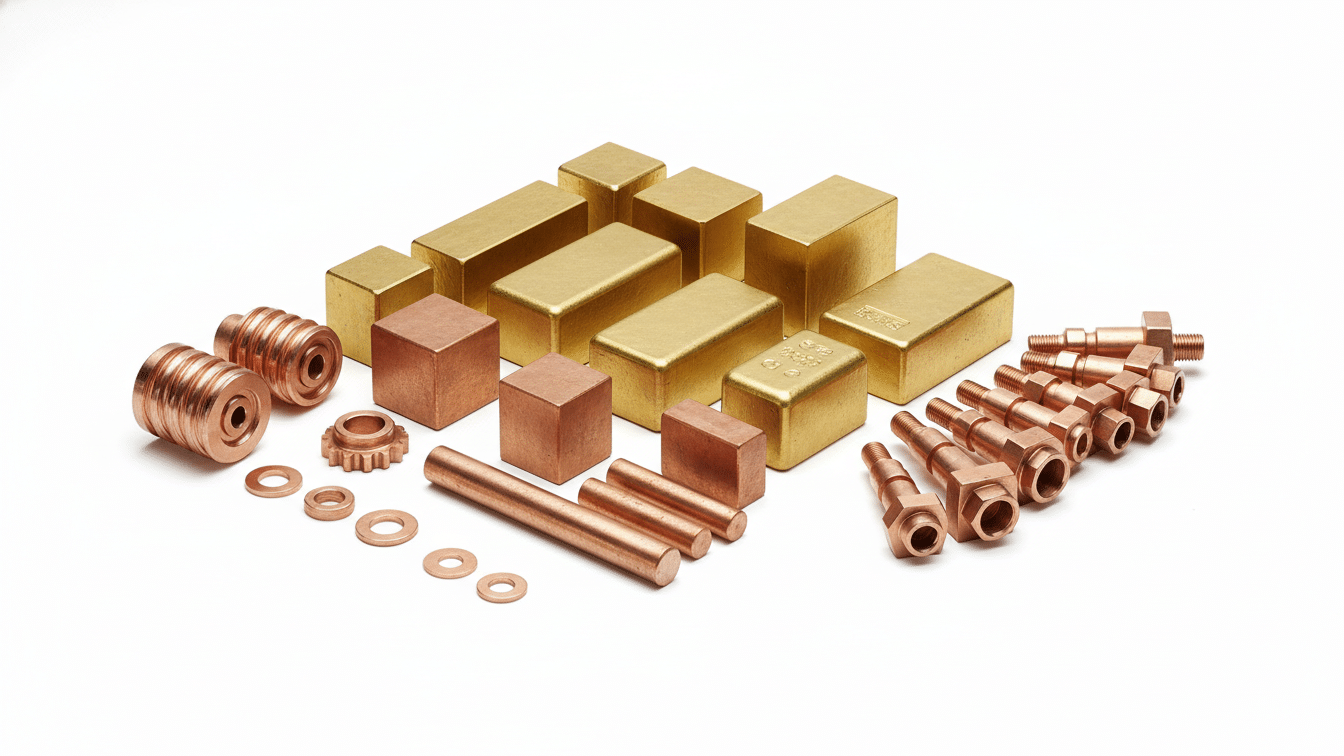

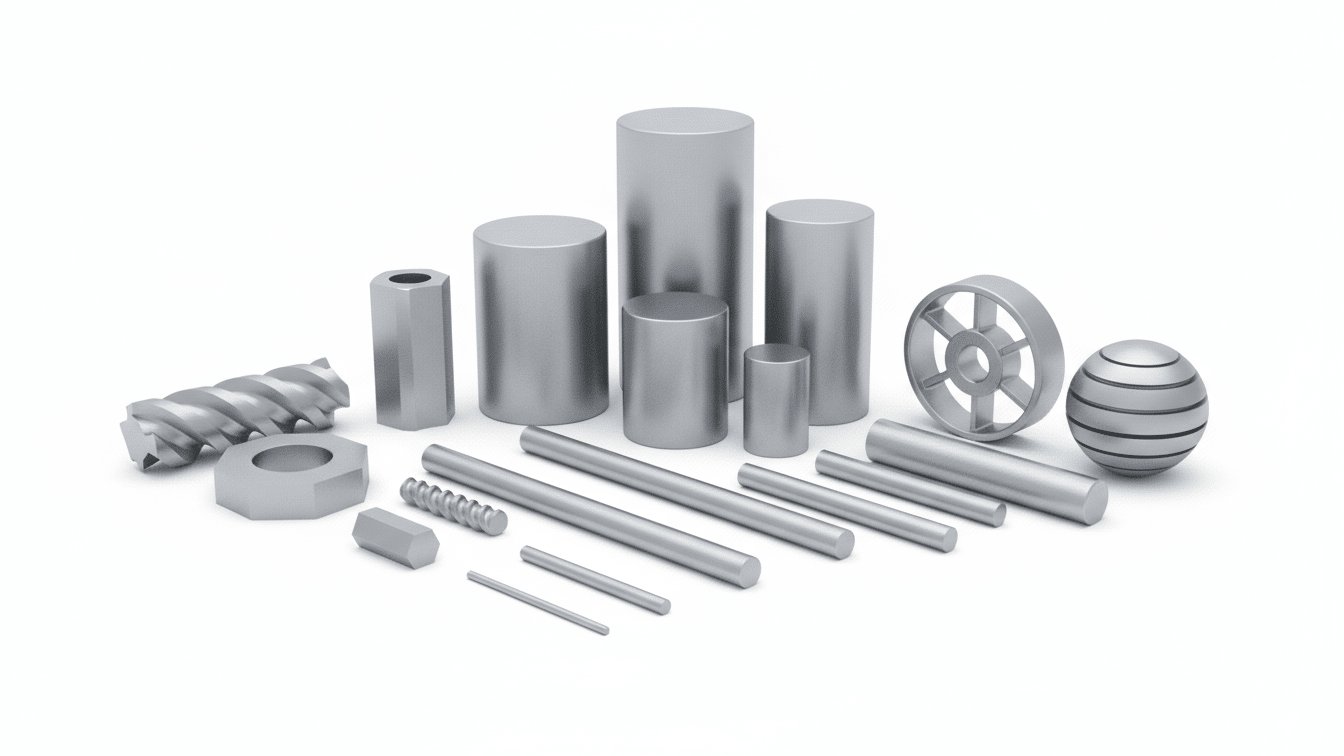

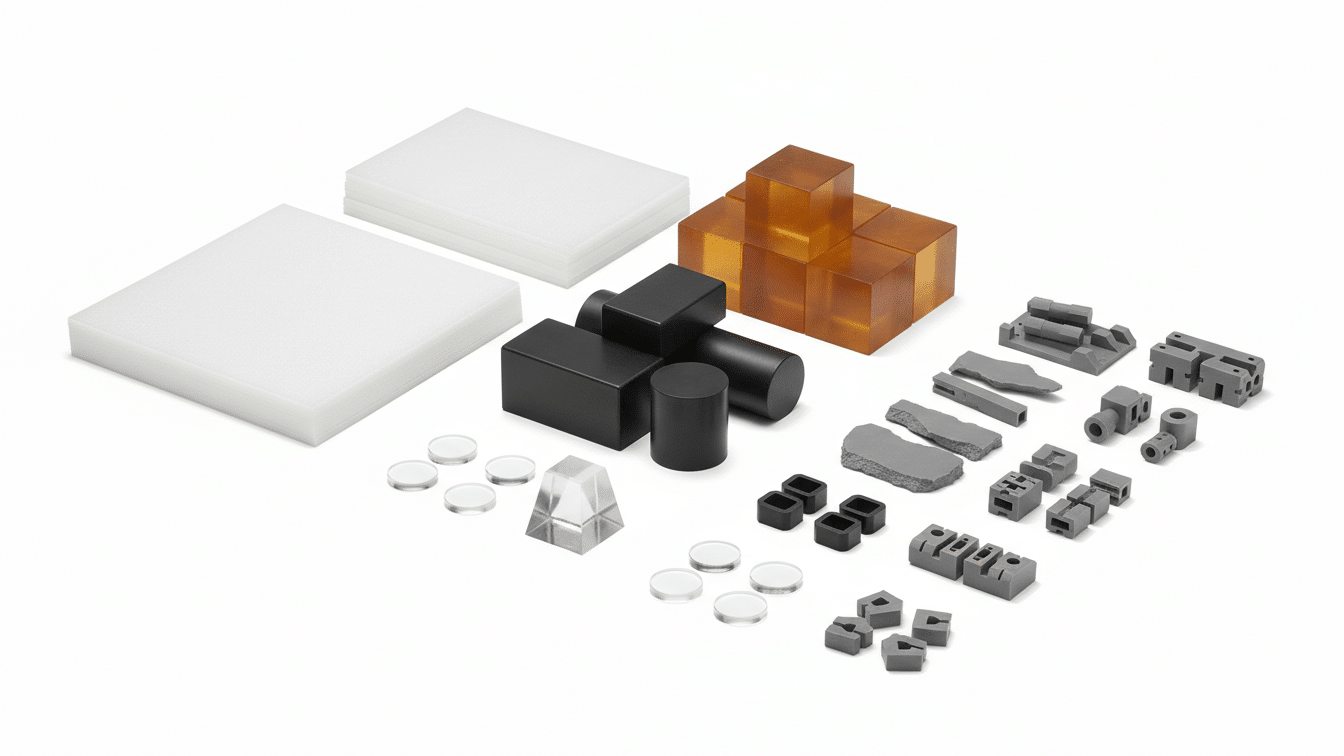

Materials We Work With

Aluminum

6061, 6082, 7075

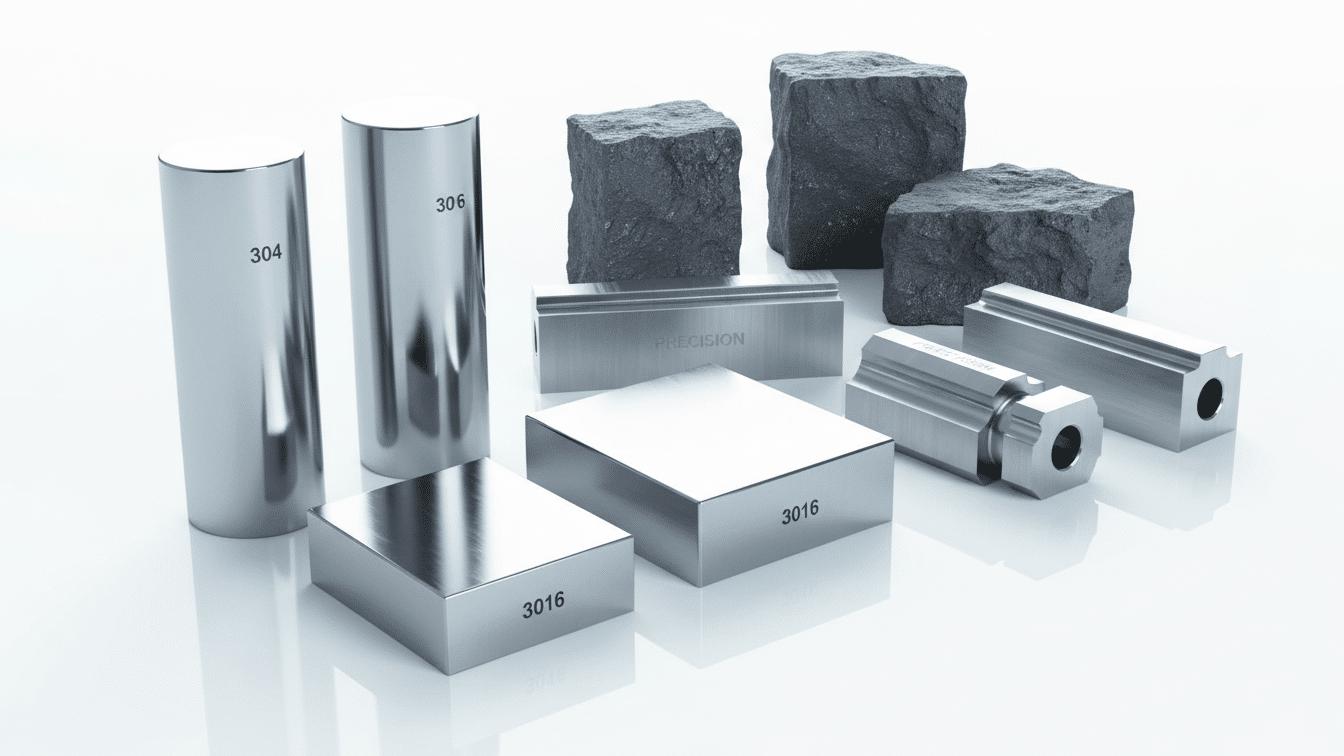

Stainless Steel

304, 316, 420

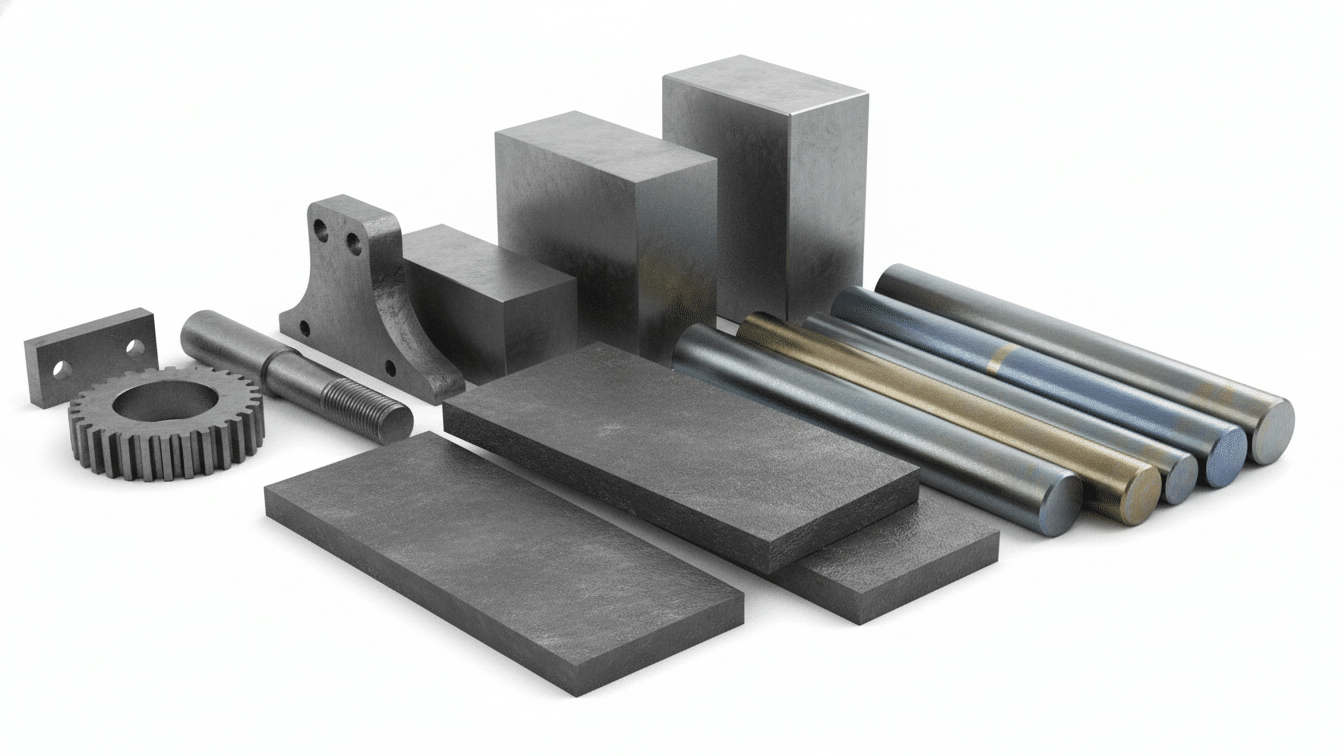

Carbon & Alloy Steel

Mild steel, 4140, 1045

Copper & Brass

C11000, C36000, C26000

Titanium

Grade 1–5

Engineering Plastics

POM, Nylon, ABS, PC, PEI

Our Capabilities

Tooling & Mold Support

VNM collaborates with certified suppliers using modern tooling and measurement systems:

- Carbide end mills & inserts

- Precision collets, fixtures, and workholding systems

- CAD/CAM programming tools

- CMM measurement, micrometers, height gauges, profile projectors

- Specialized jigs for high-repeatability jobs

These tooling assets allow stable machining accuracy, longer tool life, and predictable quality for complex tolerances.

Our Capabilities

Industries We Serve

Agriculture Machinery & Equipment

We supply durable, high-precision machined parts for agricultural machinery, ensuring reliability under heavy load and harsh working environments.

Mining & Material Handling

VNM produces robust components for conveyors, crushers, and lifting systems, built to withstand high impact, abrasion, and continuous operation.

Oil & Gas Systems

We manufacture tight-tolerance fittings, housings, and structural parts designed for high pressure, corrosion resistance, and critical performance in oilfield systems.

Automotive & Heavy Vehicles

Our machining capabilities support engine components, drivetrain parts, brackets, and connectors that meet strict automotive standards and repeatability.

Industrial Automation & Robotics

We deliver precision components for motion systems, actuators, and robotic assemblies where accuracy, alignment, and surface quality are essential.

Electronics & Precision Devices

VNM specializes in small, intricate CNC parts for sensors, connectors, housings, and high-accuracy assemblies used in electronics manufacturing.

Hydraulic & Pneumatic Systems

We machine valves, blocks, adapters, and control components engineered to maintain pressure stability and leak-free system performance.

Construction Hardware & Components

Our machining network produces brackets, fasteners, structural plates, and custom fittings used in architectural and construction applications.